Details

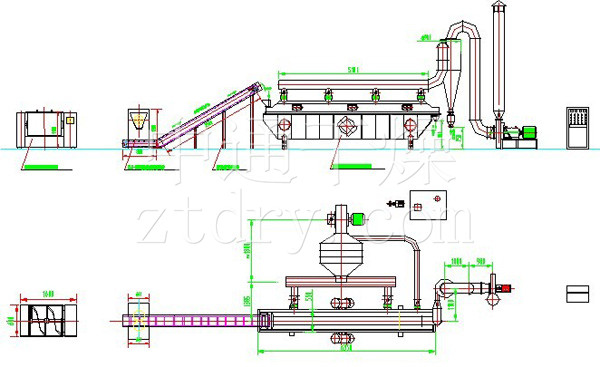

Descriptions:The production process of chicken essence include: food (wheat, corn, soybean) - semi-monosodium glutamate (monosodium glutamate) and a small amount of chicken powder and mixture accessories - granulation - drying - sieving - packaging - inspection - finished products - storage. For color, the smell of chicken products is superb; the choice of accessories is crucial. The semi-finished products of MSG on MSG (MSG) and other high-quality oils that have a decisive influence on the finished product. When dry, since the main components of chicken meat are glutamic acid and sodium glutamate, which evolve at temperatures above 120 °C, it will become the focus, sodium glutamate, harmful after eating, so the chicken is dry, the temperature of the drying chamber Must be controlled between 95 ° C and 115 ° C to give full play to the nutritional value of the chicken.

Our company has been committed to the research and development of chicken and chicken production line equipment for many years. We have developed a variety of different process packaging production line equipment, and all stainless steel equipment meets the user QS certification requirements. China has more top ten manufacturers of chicken meat sales and large manufacturers in East China to sell our chicken and chicken powder production line equipment.

Drying instructions:

In conventional fluidized bed dryer basis, made a lot of improvements to make it meet the chicken dry and production process requirements, and has been applied to a number of chicken producers, well received by users.

Easy Chicken has some sticky sticky surface caused by drying in the drying machine can not. To solve this problem our company has taken many measures. Chicken extrusion granulation after molding, the higher the surface water, the first paragraph of our production to the low-temperature fluidized bed volume of pre-drying wind, so that the surface water to quickly lower the chicken, while the surface viscosity decreased. Fluidized bed temperature and air volume in the second paragraph to dry in order to further reduce the chicken surface water. The third paragraph of conventional fluidized bed temperature and air flow to the dry chicken in the fluidized bed so that sufficient residence time to be effectively dried. The fourth paragraph of wind capacity to the cooling bed, easy chicken stock powder in the screen directly after packaging. In short, in order to meet the chicken at different stages of technological requirements, bed rate and the opening direction of the hole, and fans have the appropriate design selection.

To improve the flow of chicken dry bed of the operation results and reliability, the company increased production of fluidized bed boiling chamber volume, the host of a framework structure.